|

Current Projects for Tillso Ltd

Folding linkage mounted soil loosener to structure the soil with minimal surface disturbance having the facility to tow a

rear flexible tyre roller. This provides a platform for small seed crop establishment with optimum subsurface and surface

consolidation.

Seedbed

Cultivator Design. Tillso Limited, Spring 2012 Project

to design and detail a seedbed cultivation machine based on the recently developed Diamond Roller system. Initial prototype

was a 6m machine made for a local Customer, first used for Spring seedbed preparation 2012. Comprises levelling boards, front

tines with adjustable angle and depth, intermediate tines and two diamond roller rows to combine consolidation with levelling

and clod breaking, plus variable loosening as required. Leaves a weatherproof, ridged finish ideally suited to a range of

crops being established.

Simba DDLight600 rollers fitted to a Vaderstad Carrier 9.2m. The original bearings were retained, and rollers with scraper

rails made to fit directly in place of the original cast roll ring axles.

A further development of the Tillso Rake and Roller has been to design a dedicated tyre for the roller.

This has involved research into the dynamics of high speed rolling with tyres and has resulted in a tyre design which both

consolidates at high speed and flexes in multiple directions for seed to soil surface contact and self-cleaning.

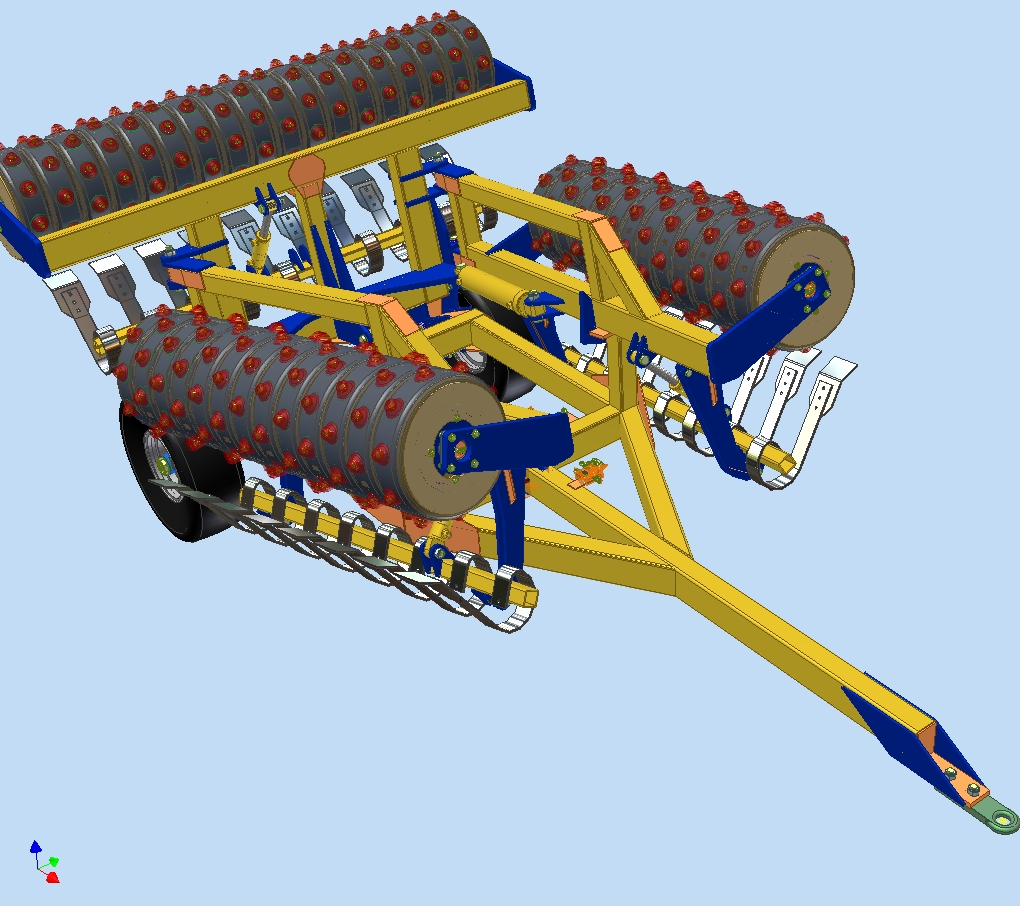

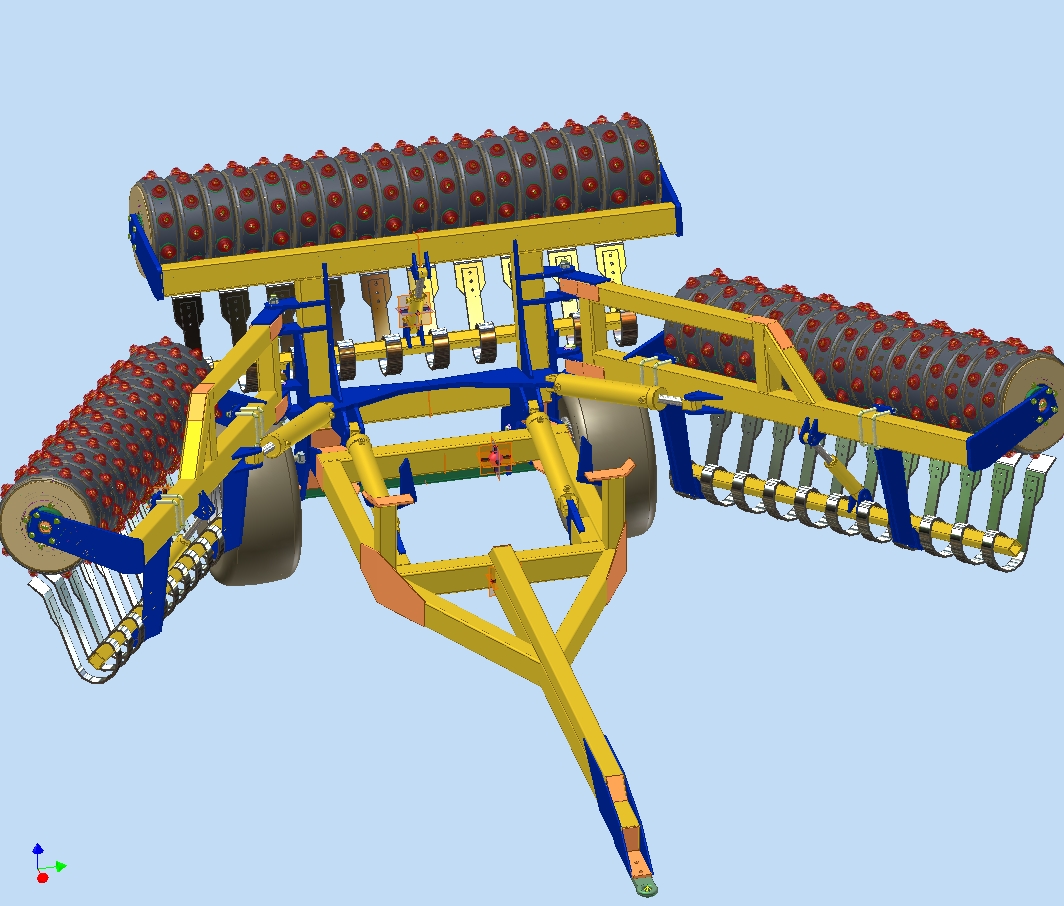

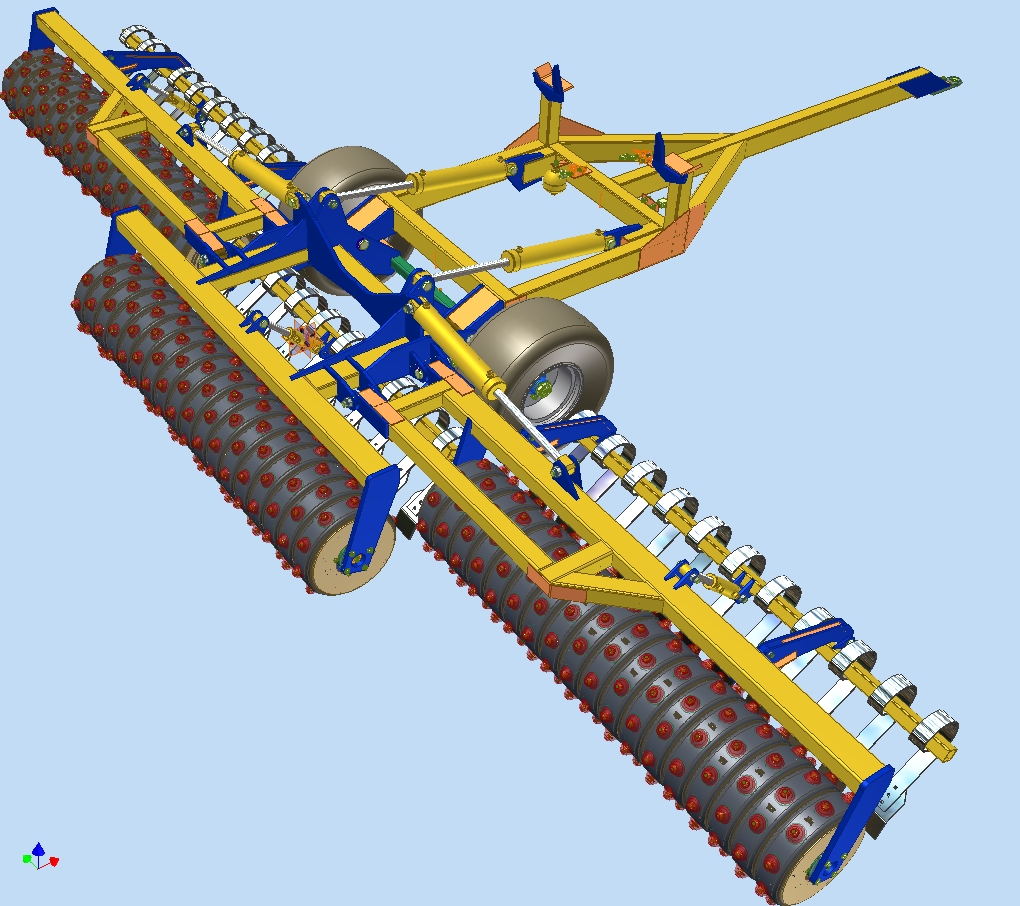

Roller

design project: The

design allows Cambridge or other rings (illustrated with the Simba Aqueel2® roll elements) to be used in a folding chassis

with a range of working widths (4.8m - 9m), with all folding to under 3m for transport. They all have the option of a

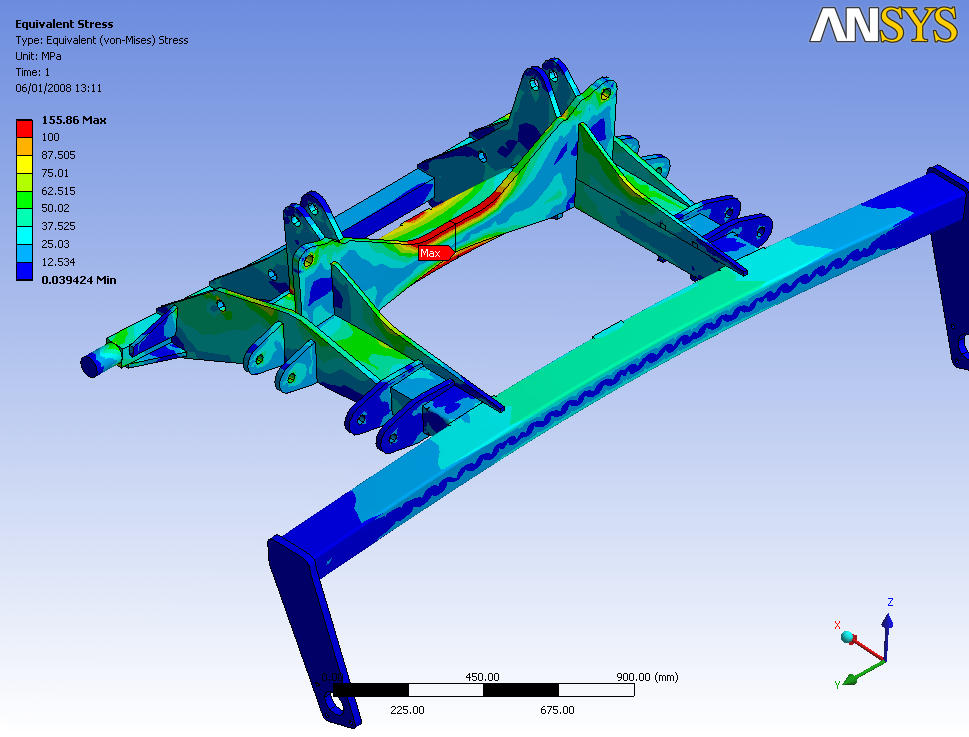

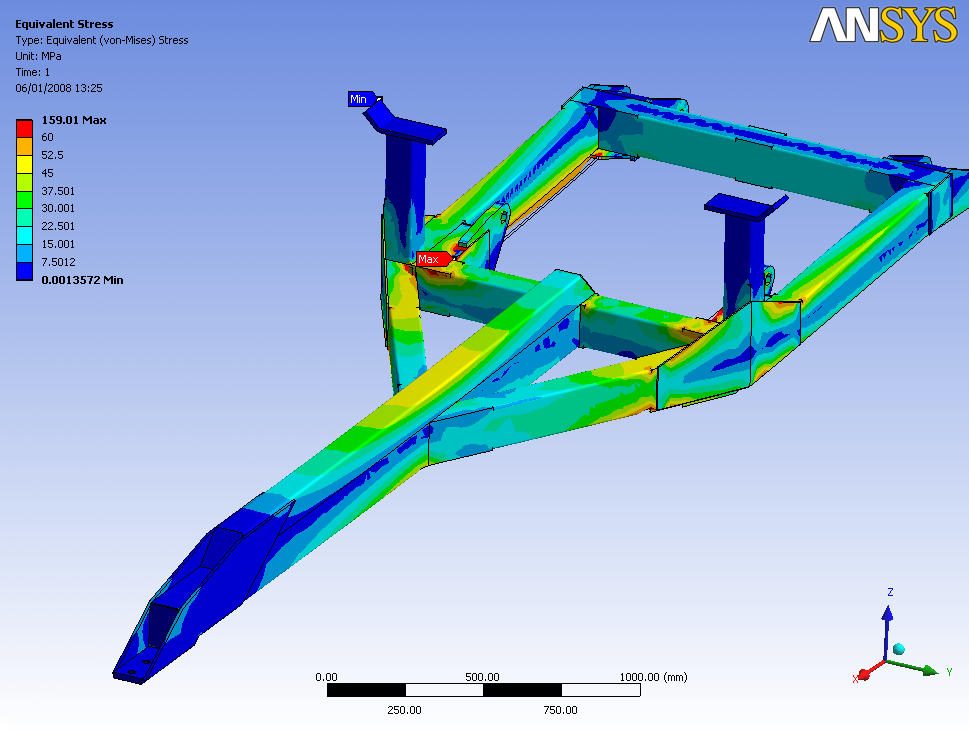

leading levelling board (hydraulically adjusted). Modelled in Inventor, the chassis loads and reactions were derived using Inventor

Simulation for both folded and working situations. The key chassis elements (drawbar and centre frame illustrated) were checked

for stress and deformation in ANSYS to ensure a cost-effective and durable design to meet the market requirements for performance

and cost. Client:Profoods KFT, Hungary.

|

|

Simba DD700 rollers attached to a Gregoire Besson Discordon. So far, 2 Discordon machines have been equipped with DD700

rollers with purpose designed bearing mountings and scraper rails to allow the axles to fit directly onto the roller frames.

Other machines equipped with DD rollers to date include a Cousins V-Form Subsoiler, a Sumo Subsoiler, McConnel Shakearators,

and various power harrows and other machinery. Aqueel type rollers have been fitted to a number of machines including power

harrows and 2 Structural Planters.

|

|

OSR

establishment guide. Client: Simba Great Plains Ltd

Cereals Guide. This booklet is the second in a series of Technical Guides prepared for Simba

Great Plains.

|

|

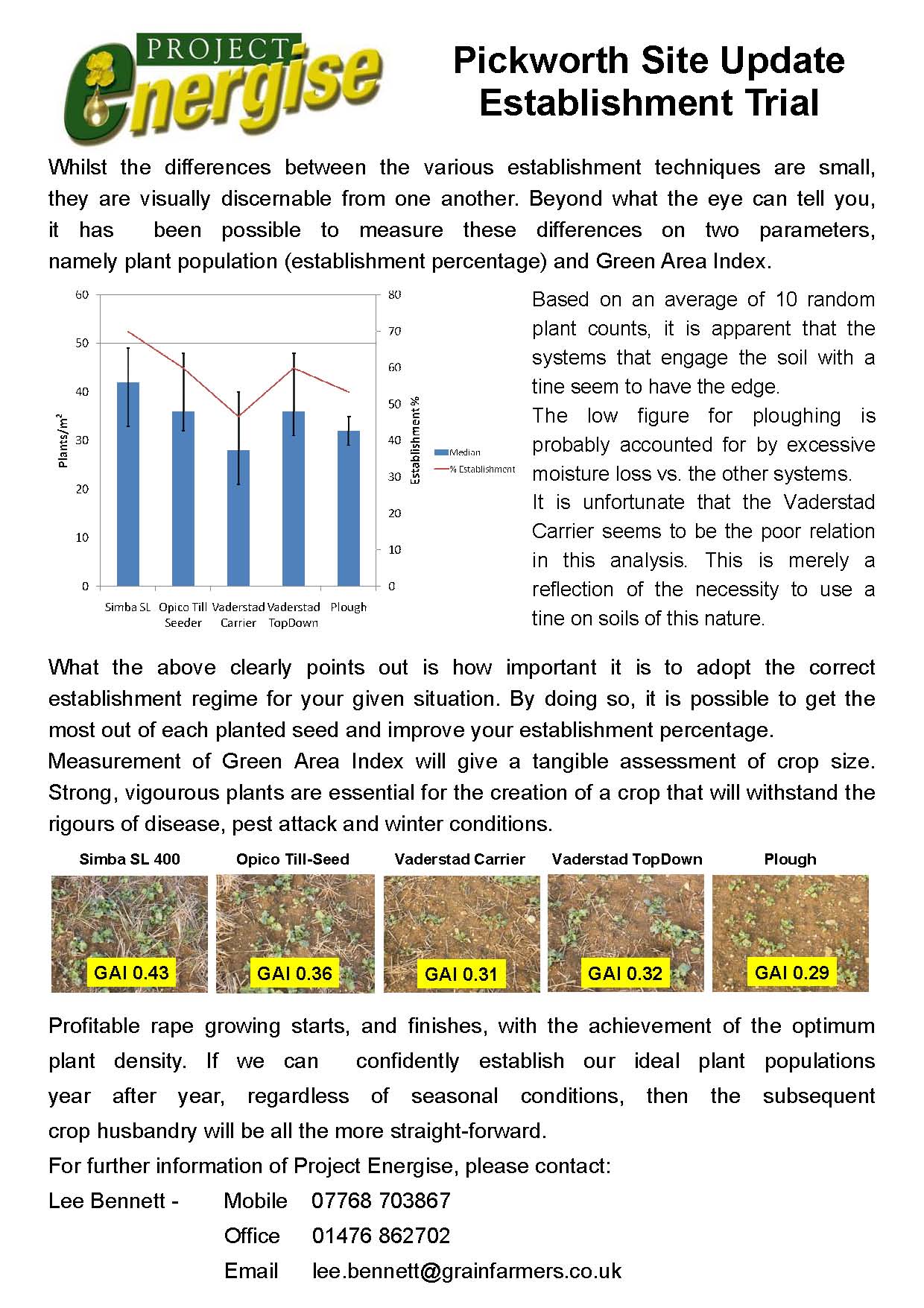

Independent

feedback from Grainfarmers resulting from the OSR establishment project undertaken for Simba Great Plains.

|

| Click on the article to read it |

Soil guide. Client: Simba Great Plains Ltd.

|